At RND Automatic, we design and build custom special-purpose machines, robotic systems, and fully automated assembly lines that help manufacturers increase productivity, precision, and reliability.

At RND Automatic, we provide end-to-end industrial automation solutions — from custom machines and robotic cells to fully automated assembly lines. Our multidisciplinary team combines mechanical design, automation, robotics, and software development to create systems that improve productivity, quality, and safety in manufacturing.

With over a decade of experience and in-house manufacturing capabilities, we control every stage of the process — design, machining, assembly, programming, testing, and on-site commissioning. This vertical integration allows us to deliver precision, flexibility, and reliability in every project.

From concept to commissioning — your automation partner for performance and innovation.

RND Automatic offers a complete portfolio of solutions — from special-purpose machines and robotic cells to assembly lines, optical inspection, industrial control, and traceability/OEE software.

Turnkey automated lines that integrate robotics, testing, and vision systems for full process control and traceability.

Designed for high productivity, flexibility, and long-term reliability.

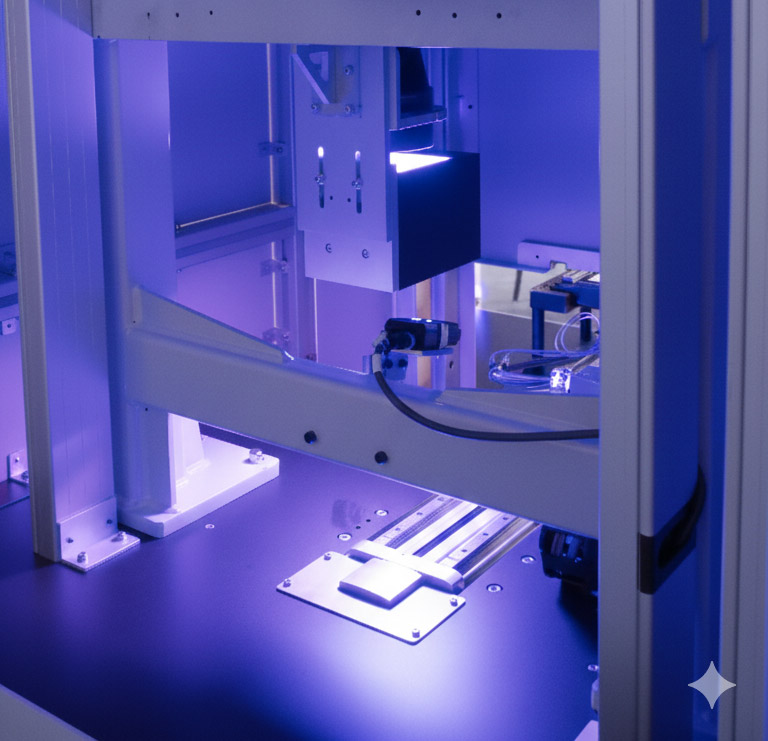

Custom machines for assembly, testing, measurement, and calibration — tailored to your production process.

Designed for precision, repeatability, and easy maintenance.

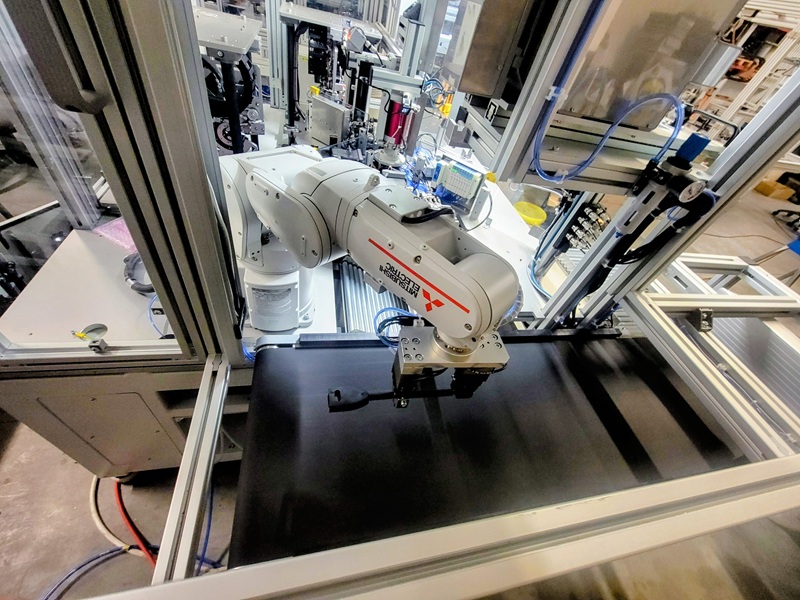

Integration of industrial robots for handling, assembly, inspection, and palletizing.

Scalable, safe, and flexible robotic solutions based on technologies from global manufacturers.

Inspection and measurement with 2D/3D vision, AI algorithms, and calibrated optics.

Ideal for quality control, defect detection, and geometric verification.

PLC, HMI, and SCADA programming with servo-system and motion integration.

Included: electrical/pneumatic/hydraulic design, electrical panels, commissioning.

Real-time data collection, part tracking, and performance dashboards.

Designed for full visibility & continuous improvement (Industry 4.0).

To ensure the highest quality and fast execution times for every automation project, RND Automatic operates its own CNC machining workshop.

Equipped with modern equipment and experienced operators, we produce precision components, fixtures, and clamping systems that ensure mechanical accuracy and long-term reliability across all our automation systems.

In addition to supporting internal projects, our machining division also provides subcontract CNC services for external partners — from prototypes to small-batch production.

See details

from the first concept to final commissioning.

We start by analyzing production objectives and defining the technical solution. Our engineers validate the concept, cycle-time estimates, and cost-optimization studies.

Mechanical, electrical, and automation design are done in-house. We combine CAD modeling, control schematics, and simulations to ensure functional safety and maintainability.

Precision parts are produced in our CNC workshop and assembled in our factory in Satu Mare. This ensures quality, repeatability, and short lead times.

Each system is tested for functionality, accuracy, and safety before delivery. We provide full documentation, CE compliance, and acceptance testing together with the customer.

Our specialists handle on-site installation and operator training for smooth integration into the production line.

We provide warranty services, preventive maintenance, and software updates to keep equipment at peak performance.

Our solutions combine mechanical precision, advanced control systems, and intelligent vision tools — tailored to each customer’s production environment.

From automotive to medical, we understand the technical, quality, and traceability requirements specific to each sector.

Automated assembly, testing, and marking systems for safety-critical components (seat belt mechanisms, connectors, sensors, mechanical components). We comply with strict quality and traceability standards required by Tier-1 / Tier-2 suppliers.

Special-purpose machines and robotic systems for subassemblies, testing, and part identification in mechanical and electromechanical manufacturing processes.

Automation for assembly and testing — from plastic parts and fittings to modules and electrical controls. We increase consistency, reduce manual work, and ensure long-term reliability.

Flexible robotic systems for handling, palletizing, and sorting, based on automated optical inspection — for higher productivity and less manual handling.

High-speed assembly, laser marking, and testing machines designed for compact parts, PCB modules, and plastic components.

Our in-house capabilities for design, machining, assembly, and automation allow us to deliver projects faster, with high precision and full quality control.

We don’t just build machines — we build long-term partnerships based on trust, communication, and results.

Over 300 automation projects completed in Europe, in compliance with CE standards and customer requirements — from project validation to final testing.

Whether you need a custom machine, a robotic cell, or a fully automated production line, our engineering team is ready to turn your vision into a reliable, high-performing solution. We work closely with your team to define requirements, design the optimal process, and deliver a system that meets your productivity, quality, and efficiency targets.

Work with a team that understands engineering, precision, and performance.

Contact us